What makes the difference in the performance of pH, ORP and H2 for each Water ionizer?

Regardless of the price or number of plates, the newly purchased ionizer has no problem producing alkaline water suitable for drinking and healthy for at least a week to a maximum of a month.

However, it can be observed that the ionizer’s pH, ORP, and dissolved hydrogen values decrease over time.

The reason is that alkaline minerals create plaque buildup on the platinum plates and the surface of the membrane. And this fatal problem worsens rapidly as the number of electrodes(plates) increases.

The reason is that alkaline minerals create plaque build-up on the platinum plates and the surface of the membrane.

If these mineral plaques are not removed in time, they will gradually calcify, the electrolysis capacity will be lowered, and thus the performance of pH, ORP, and dissolved hydrogen will deteriorate.

(Those who regularly scale their teeth will understand the above explanation more easily.)

Therefore, the pH, ORP, and H2 performance of the ionizer is not the number of electrodes or the high or low cost, but effectively preventing these mineral plaques on the electrode and membrane is the key to determining the performance of the ionizer.

The principle of Reverse Polarity Cleaning

Reverse polarity cleaning is when your ionizer reverses the polarity; positive electrodes become negative and conversely.

When an electrode is “bathed” in alkaline water containing scaling minerals, it becomes susceptible to mineral scale. When the polarity is reversed, the same electrode is exposed to acidic water, which removes the mineral scale.

Because it is acidic water to descale, there must be an optimal “acid to alkali wash ratio” in the wash cycle for optimum efficiency.

Alkali-to-acid ratio for most effective reverse polarity cleaning

Studies have shown that it should be at least a 50:50 ratio reverse polarity cleaning to prevent mineral scaling.

In other words, if you use 1 liter of alkaline water, you must change the polarity of the electrode used in alkaline water and then clean it with 1 liter of acid water to generate optimal alkali, ORP, and dissolved hydrogen.

Although almost all ionizers use a reverse polarity cleaning type, most have used an outdated cleaning system for decades without advancement or technological improvement.

For this reason, there is a problem that alkaline water cannot be used during the cleaning process because the electrode of alkali and acid and each outlet are reversed during the cleaning process.

Fortunately, a new and innovative technology called DARC has been developed that can replace these outdated cleaning systems and prevent mineral scale of the electrode and membranes.

DARC technology is based on the idea that mineral plaque can be prevented by periodically exchanging the polarity of the electrodes during electrolysis.

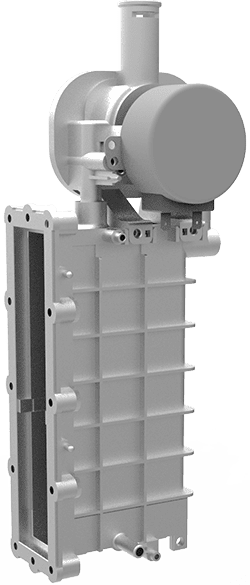

DARC water-cell(electrolyzer) is equipped with rotary valves that change the path of water at the outlet for discharging alkaline and acidic water.

This rotary valve is connected to the microcomputer. When the microcomputer reverses the electrode’s polarity, the rotary valve also rotates, and the outlet pipe inside the valve matches the outlet path of alkaline water and acidic water.

Thus, consumers can use the ionizer regardless of cleaning process.

As the cleaning system is essential, it can be classified into three methods according to the technology.

Each cleaning system can also be classified into its type in its own way.

First, a “Program Cleaning” method that cleans according to a specific program

Second, a “Chemical Cleaning” method of cleaning by injecting chemicals directly into the machine from the outside

Third, a “DARC Cleaning” it is an ionizer brand that introduced the most innovative new technology, ‘DARC cleaning.’

Classification of each cleaning method and the difference

1) Program Cleaning Method - 4Tyes

Program Cleaning Type 1 : Manual system (Acidic Buttons)

You must remember to reverse the polarity and initiate the cycle yourself.

This manual system is an acid water button essential to all ionizers.

Most brands are telling it as a function designed for washing or sterilizing.

Still, this function is an acidic water wash to the alkaline electrodes just after using alkaline water to prevent mineral plating on alkaline electrodes.

Program Cleaning Type2 : Post cleaning systems

While they clean after each use, the clean cycle is extremely short, resulting in a poor acidic-to-alkaline ratio.

Since cleaning starts after the ionizer is off, only the water in the electrolyzer is used. Therefore, it is impossible to sufficiently clean the alkaline electrode and mineral scale with acidic water.

Program Cleaning Type 3 : Timer system

Cleans at a set interval, such as every 15 minutes of use. After 15 minutes of run time, the next time you turn the ionizer on, the unit starts the cleaning cycle. Most often, you must wait while it completes the process.

Program Cleaning Type 4- Volume system:

Similar to the timer system, but cleans based on a set volume of water (Say, for example, 10 liters) passing through the ionizer. You must also wait.

Each outdated cleaning system has drawbacks: you may need to remember to wash alkaline electrodes with the acidic button every time or feel annoyed, and the timer and volume systems have poor acidic-to-alkaline cleaning ratios. The worst fault is that with each of the above procedures, you have to wait for the cycle to complete before you can receive alkaline drinking water.

Classification of each cleaning method and the difference

2) Chemical Cleaning – 2Types

Chemical Cleaning Type 1 : Cleaning Filter (or Descale Filter)

A cleaning filter must be purchased separately from the ionizer filter.

The inside of the cleaning filter contains chemicals that can dissolve alkaline minerals. This chemical is injected with water into the ionizer to dissolve the alkaline minerals in the internal pipes and the electrolytic cell. Still, in practice, it can be said that there is almost no effect.

In addition, since the cleaning filter cannot be reused after being washed once, there is a cost burden to purchasing a separate cleaning filter in addition to wasting resources.

Chemical Cleaning Type 2 : Deep Clean Tools (Descale Tools)

The second chemical cleaning method uses a device modified from a circulator for home aquarium basin water in a tank called a “Deep Clean Device” on the outside of the machine.

After filling the device with water in which a chemical substance is dissolved, this chemical substance circulates through the pipes and electrolyzer inside the machine from a minutes to hours, to dissolve the alkaline minerals.

This also makes it impossible to use the ionizer while the circulator runs, along with the additional cost of separately purchasing a water circulation circulator called Deep Clean.

Moreover, it is easy to overlook that chemicals that are strong enough to dissolve the limescale damage the electrolytic cell diaphragm(membrane), which is made up of a thin plastic fiber membrane with micropores through which the electrolytic cell minerals pass.

And the most worrying thing is that if the diaphragm(membrane) is damaged, alkali and acid are mixed and discharged together, and even residual chlorine is detected in alkaline water.

Classification of each cleaning method and the difference

3) The DARC - Advanced Cleaning System

DARC Type1 : The DARC (Dual Automatic Reverse Cleaning

DARC cleans with every use, eliminating damaging scale buildup. It accomplishes this by reversing polarity each time you use the ionizer.

The revolutionary DARC cleaning system eliminates mineral scaling on the electrodes and membranes.

DARC is highly effective because it works in the background to clean your electrode each time you use your ionizer and while you are using it.

Additionally, with the dual solenoid system that directs water flow, you never have to wait while your ionizer cleans to get your alkaline water.

DARC Type2 : The DARC + Hybrid Cleaning (DARC + Post Cleaning)

Alkaline minerals are most likely to be plaque at the alkali outlet of the

ionizer equipped with the DARC function.

Therefore, the DARC + Hybrid Post Cleaning is set in the Alpha ionizer to prevent alkali minerals from plating inside the alkaline flexible outlet.

After turning off the power, the acid water is automatically discharged for the time set by the consumer to sterilize the inside of the tube and the water tank. The residual alkali minerals are dissolved in acidic water and discharged forcibly through the drain outlet.